If you want to choose the right product between two same kinds of Permatex products, you must know everything about them and the Permatex Ultra Copper vs. Red comparison first.

Permatex products are great for their features, easy-to-use process, and versatility. Many products come in different colors. They work differently. The copper one is for high-temperature applications.

The red one is also the same, but it works at a higher temperature than the copper one. It creates a non-removable bond that is best for heavy-duty projects as well.

To know detailed information about Permatex Ultra Copper and Red, get through the comparison first.

Read More: Permatex Ultra Grey vs. Ultra Black

Permatex Ultra Copper Vs. Red

About Permatex Ultra Copper

Permatex Ultra Copper RTV silicone gasket maker is a high-temperature one to work on exhaust systems like exhaust manifolds/headers, slip-fit exhaust parts, turbocharger applications, and other high operating temperatures.

It is the advanced one that is sensor-safe, non-corrosive, and has low odor. Besides, it is easy to use, even on high-temperature applications. The temperature range of this product is -65°F to +700°F Int. (-54°C to +371°C).

Also, the Permatex Copper one is ideal for exhaust gasket repair because it has a high flexibility feature that makes it easier and more effective.

Moreover, it resists auto and shop fluids. It has three times more oil resistance than conventional silicones and eight times more flexibility than cut gaskets.

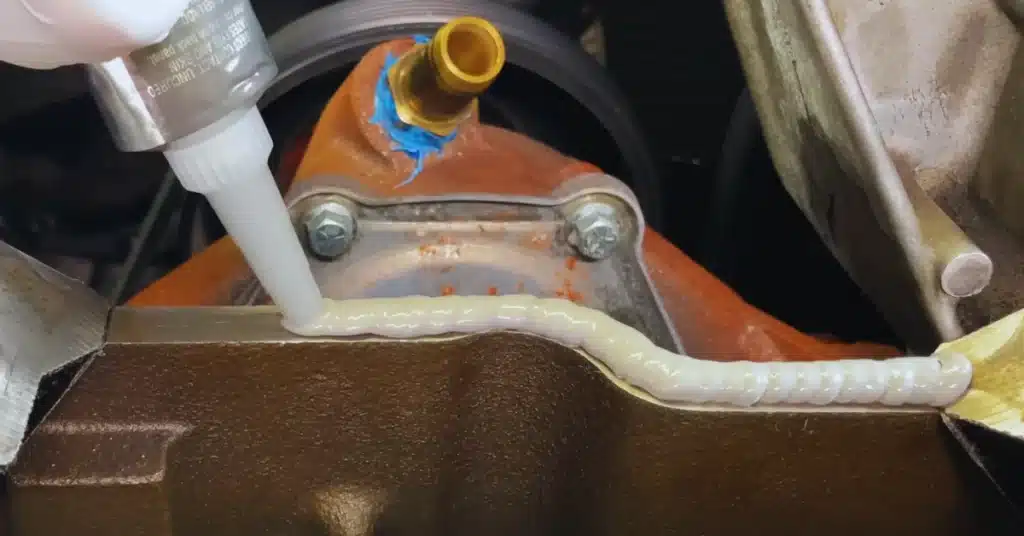

Permatex Ultra copper has a metallic copper color. It has an orangish tint that can stain the places. So, you have to be careful while using it. Make sure it doesn’t get messy.

You should seal the gaps between the body and the top of a Weber to control the temperature when using the copper gasket maker.

Also, you can coat the kettle with Vaseline because it helps to prevent sticking. Use the Permatex copper to get the best outcome at higher temperatures.

About Permatex Ultra Red

Permatx Ultra Red is the one with higher temperature resistance than any others. It has a low-odor formulation.

It is the one that outperforms the previous gen. You can use it for manifold, header, turbocharge, slip-fit exhaust parts, and more.

Talking about its high-temperature facility, it works at a temperature of up to 650°F (343°C). It is not only resistant to high thermal cycling but also is sensor-safe.

This non-corrosive RTV silicone gasket maker can replace almost any cut gasket. Moreover, it ensures a fast curing time. Within 8 hours, it gets fully cured and ready to use.

Besides, this chemical gasket maker can withstand high thermal cycling. It is non-toxic, non-flammable, and OEM certified.

If you want a non-toxic RTV silicone that meets the performance specs of OE silicone gaskets, this is the ideal one.

With the resistance to most common shop fluids, the Permatex Ultra Red becomes the most efficient one with good qualities.

Read More: Permatex Motoseal vs. Ultra Grey

What Is The Difference Between Permatex Ultra Copper And Red?

The main difference between these two products is that Ultra Red has better features and a higher temperature facility to work on the projects.

The Permatex Ultra Copper is for high-temperature applications like turbochargers and exhaust systems. The Permatex Ultra Red One can do the same but better.

The Ultra Red is the next-generation product. That means it replaces the previous gen with its excellent features and workability.

Both products are sensor-safe, OEM-certified, and ideal for high-temperature projects. But if you want a better outcome with an upgraded gasket maker, the Permatex Ultra Red is the right choice.

Besides, the Ultra Red has a higher temperature range to work with than the copper one. The Ultra Red one offers non-toxicity, non-corrosive, and low-odor features. And it makes the product better than the Ultra Copper one.

Another thing is, the copper one leaves an orangish stain on the places where you have used it. So, you have to be super careful when using the product.

But the Permatex Ultra Red doesn’t have this issue. It doesn’t contain any color and thus leaves no stain. So, also in this case, the Permatex Ultra Red is a better solution than Permatex Ultra Copper.

Read More: Permatex the Right Stuff Grey vs. Black

What Is Permatex Ultra Copper Used for?

Permatex Ultra Copper is used for high-temperature applications. This high-temperature RTV gasket maker is better in every way. It is sensor-safe, non-corrosive, and OEM certified.

It has temperature resistance up to 700°F (371°C). All these things make it better for high-temperature applications like exhaust systems and turbocharger applications.

What Is Permatex Ultra Red Used for?

Permatex Ultra Red is used for high-temperature applications like slip-fit exhaust parts, headers, manifolds, turbochargers, and more.

It is also used for replacing pre-cut gaskets. It is considered the next-gen RTV for its incredible and updated features.

What Are The Different Colors of Permatex?

Permatex comes in different colors that have different strengths, features, working ability, curing time, and temperature range. Such as the Permatex Orange is a high-strength removable one. It can be easily removed.

Further, the blue one is also an easy-removable product. It is used for low-strength applications like oil pan bolts, valve cover bolts, and more.

Unlike them, the red one is for high-strength applications which is non-removable. The green one is for differentials and transfer cases.

The black one is for heavy-duty applications like oil pans, older domestic vehicles, oil pumps, valve covers, timing covers, and more. The grey one is for manifolds, newer & imported domestic vehicles, and thermostat housings.

Last Opinion

Now that things are clear about these two Permatex products, you can choose the better one for your project.

According to all the details about Permatex Ultra Copper vs. Red, now you know that Permatex Ultra Red is the better and the stronger one.

If you want a solid and non-removable bond, you need the red one. And if you want a regular bond, then the copper one is also good.

Select the one according to your preference and demand of the project.