There are more brands of epoxy adhesives in the market than you can count. From epoxy putty to epoxy gel, the varieties are virtually endless.

However, when it comes to the best epoxy adhesives, there are a few, and among these few, PC 7 Epoxy and JB Weld stand out.

They are strong, capable, and durable. And when it comes to choosing between them, more often than not, you might get confused.

That’s why I have compared PC 7 Epoxy vs. JB Weld and highlighted their differences for your convenience.

Go through the article below to learn more.

Read More: JB Weld Vs. Epoxy

Read More: JB Weld vs. Pratley Steel

PC 7 Epoxy vs. JB Weld

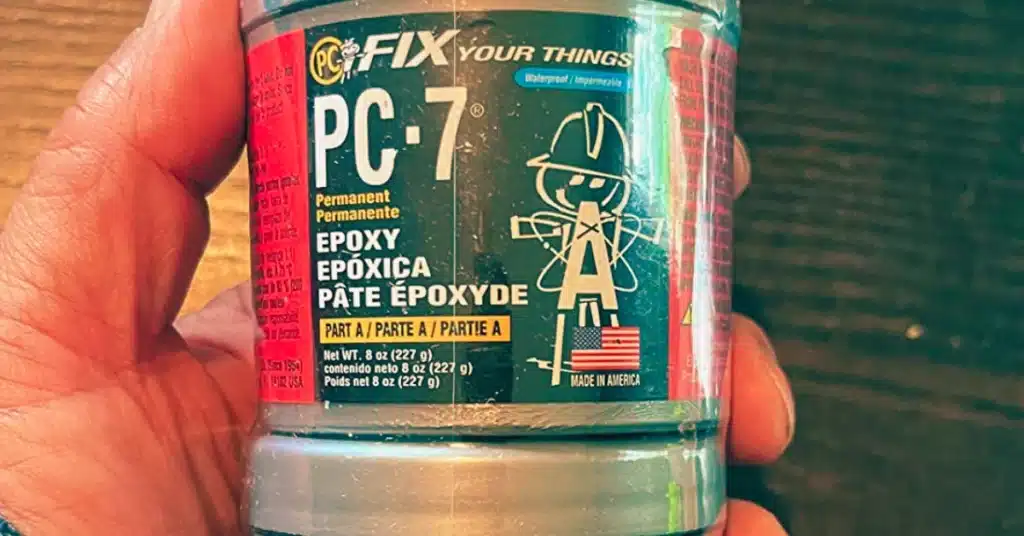

What Is PC 7 Epoxy?

PC 7 Epoxy is a medium-strength epoxy adhesive that is used to bond anything and everything you can think of. From creating a strong bond between metals and wood to ceramic and others, this glue works on anything and everything.

Originally formulated more than 60 years ago, this epoxy adhesive is strong and durable. It offers permanent repairs and bonding for your convenience.

Also, as this epoxy adhesive is oil and chemical-resistant and can withstand high temperatures, it enhances the durability of the bond like none other.

What Is JB Weld?

J-B Weld is yet another type of epoxy adhesive that provides a strong and durable bond between surfaces.

Featuring a high tensile strength of 5020 PSI, this cold-weld two-part epoxy system can create a lasting bond on a variety of surfaces. From metal to wood and even automotive, the use of this glue is versatile.

That’s not all. When fully cured, JB Weld adhesive can withstand up to 550ºF of heat to ensure exceptional durability to the users.

Read More: Bondo vs. JB Weld

Summary of The Differences

Even though both the PC 7 Epoxy and JB Weld are epoxy adhesives, there are some major differences between them.

I have listed these differences in the comparison table below for a quick understanding.

| Properties | PC 7 Epoxy | JB Weld |

| Viscosity | Extremely High | Good |

| Working Time | 1 hour | 6 hours |

| Cure Time | 48 hours | 24 hours |

| Bonding Strength | 2150 psi | 5020 psi |

| Heat Resistance | 200ºF | 550ºF |

Read More: JB Weld Vs. Gorilla Glue

Top 4 Differences Between PC 7 Epoxy and JB Weld

Now that you know the differences between PC 7 Epoxy and JB Weld, let me discuss them in detail for your better understanding.

Viscosity

Even though both the PC 7 Epoxy and JB Weld adhesives are quite similar, their viscosity differs significantly.

For starters, PC 7 Epoxy is a high-viscosity adhesive that offers superior bonding and gives you enough time to control the assembly process.

On the other hand, JB Weld also has high viscosity, but not as high as PC 7 Epoxy. It also creates a strong bond and gives you ample time to control the assembly process.

Cure Time

When it comes to the cure time, there is a major difference between PC 7 Epoxy and JB Weld.

Because PC 7 Epoxy is a high-viscosity adhesive, it takes about 48 hours to cure completely.

However, the same isn’t true for JB Weld adhesive. Even after having a good viscosity, this adhesive dries out quickly and fully cures within 24

Bonding Strength

The bonding strength matters. Although PC 7 Epoxy is a high-viscosity adhesive that offers a permanent bond between surfaces, it isn’t as strong as you might think.

The PC 7 adhesive has a tensile strength of 2150 psi and, hence, isn’t as strong as its competitor.

On the contrary, JB Weld is super strong, just as it claims. This adhesive has a high tensile strength of 5020 psi, which means that it has superior bonding power.

JB Weld won’t come off anytime soon.

Heat Resistance

Just like the bonding strength, both the PC 7 Epoxy and JB Weld adhesives have different heat resistance levels.

Like many other adhesives in the market, PC 7 Epoxy can withstand 200ºF of heat before melting down and loosening the bond.

But JB Weld is super durable. It can resist a high temperature of 550ºF before damaging the bond.

How strong is PC-7 epoxy?

PC-7 epoxy is a high-strength adhesive known for its exceptional bonding properties. When properly mixed and applied, it creates a very strong and durable bond.

The exact strength of PC-7 epoxy can vary depending on factors such as the materials being bonded and the curing time, but it is generally considered suitable for a wide range of applications, including those that require a high degree of structural integrity.

What is PC-7 epoxy used for?

PC-7 epoxy is a versatile adhesive that can be used for various applications, including:

- Woodworking: It is commonly used for bonding, filling, and repairing wooden structures, such as furniture, frames, and woodworking projects.

- Metal Repairs: PC-7 epoxy is effective for repairing metal components, including vehicle parts, tools, and machinery.

- Concrete and Masonry: It can be used to fill cracks, holes, and gaps in concrete or masonry structures.

- Ceramics and Stonework: PC-7 epoxy is suitable for bonding and repairing ceramic and stone items, such as pottery and tiles.

- Plastic Repairs: It can bond and repair various plastic materials, making it useful for fixing plastic components or items.

- General Household Repairs: PC-7 epoxy can be used for a wide range of everyday repairs, including those related to household items, appliances, and more.

- Marine and Automotive Repairs: It is often used for repairing boats, automotive parts, and other applications exposed to water or extreme conditions.

Last Opinion

From the PC 7 Epoxy vs. JB Weld, you now know the differences between these two epoxy adhesives.

As good as both these adhesives are, I suggest choosing JB Weld, and for valid reasons. This adhesive is stronger, more resistant, and cures quickly. It would offer you more durability than PC 7 Epoxy.

But then again, the choice is yours. Just pick the one that would serve your needs.