Thread lockers are adhesives that prevent threaded fasteners from loosening due to vibration, shock or thermal expansion. Both Loctite 246 and 243 are anaerobic adhesives, which means they cure in the absence of air.

Loctite 243 is an ideal general-purpose thread locker, capable of withstanding moderate shock and temperature variations. Loctite 246 may be more suited to heavy-duty applications, high temperatures or corrosive environments.

In this article, I will compare two popular medium-strength blue thread lockers, Loctite 246 Vs. 243.

Read More: Loctite 242 vs. 243

Loctite 246 Vs. 243

Overview of Loctite 246

Loctite 246 is commonly used in various industries, including automotive, aerospace, and industrial manufacturing. It is a medium-strength blue thread locker that works on all metals and is tolerant of minor contamination due to industrial oils.

Loctite 246 can be applied before or after assembly and disassembled with hand tools. It has a high resistance to shock, vibration and stress levels and can withstand temperatures up to 230°C (446°F).

Loctite 246 is specially formulated for heavy-duty applications, such as bolts used in transmissions, construction equipment or railroad assemblies. It does not contain any solvents and has a longer shelf life than other thread lockers.

Read More: Loctite 7471 Vs. 7649

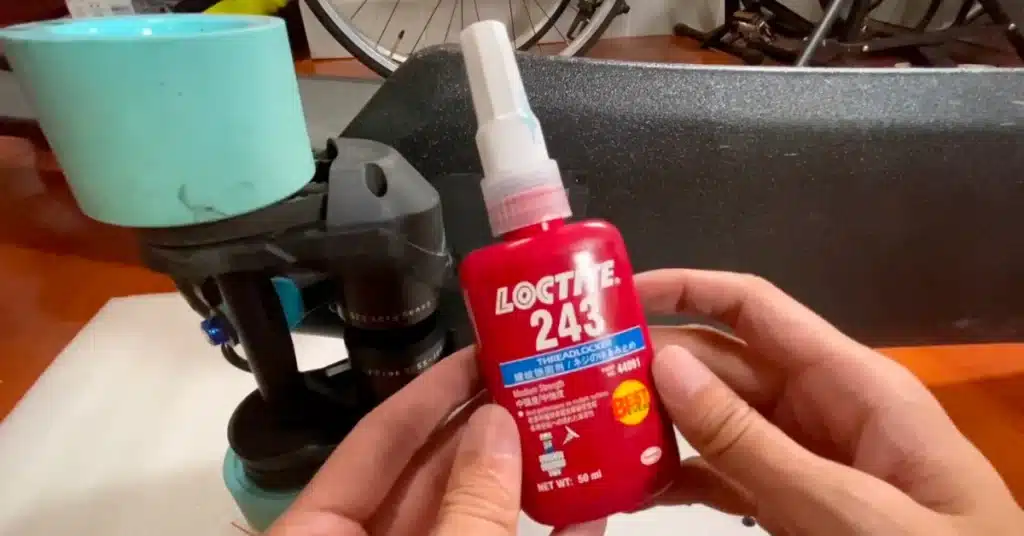

Overview of Loctite 243

Loctite 243 is a reliable and medium-strength thread locker adhesive that provides a strong and removable bond. It is designed for locking and sealing threaded fasteners between 1/4″ and 3/4″ (6 to 20 mm).

Loctite 243 is a blue liquid adhesive that is applied using a dropper or brush. It is an oil-tolerant, removable, medium-strength blue thread locker.

It works on all metals, including passive substrates such as stainless steel, aluminum and plated surfaces. It is proven to be tolerant of minor contamination due to industrial oils, e.g., motor oils, corrosion prevention oils and cutting fluid.

Read More: Loctite 248 Vs. 243

Comparison Between Loctite 246 and Loctite 243

| Feature | Loctite 246 | Loctite 243 |

| Color | Blue | Blue |

| Strength | High | Medium |

| Viscosity (cP) | 1,000 – 5,000 | 1,000 – 5,000 |

| Torque Range | 100 to 1,000 ft-lbs (135 to 1,356 N-m) | 100 to 3,000 ft-lbs (135 to 4,072 N-m) |

| Temperature Resistance | -65°F to 450°F (-54°C to 232°C) | -65°F to 360°F (-54°C to 182°C) |

| Removal | Removable with heat and tools | Removable with heat and tools |

Which One Should You Use? Loctite 246 or Loctite 243?

Both Loctite 243 and Loctite 246 are high-performance thread lockers that offer reliable and secure fastenings. However, Loctite 246 is more suitable for more extreme conditions, while Loctite 243 is better for general-purpose applications. Ultimately, it depends on the specific requirements of your application.

If you are working on a project that requires a medium-strength thread locker, Loctite 243 is the best choice. It is easy to use, provides a reliable seal, and can be removed using hand tools.

If you need a high-strength thread locker that can withstand extreme conditions, Loctite 246 is the way to go. While it requires more effort to disassemble, it provides a stronger bond that will hold up over time.

Read More: Loctite 243 vs. 263

Is Loctite 243 Removable?

Yes, Loctite 243 is removable. However, it is recommended that it be removed with hand tools in an inert environment.

Does Loctite 243 Work on Stainless Steel?

Yes, Loctite 243 works on stainless steel. It works on all metals, including passive substrates such as stainless steel, aluminum and plated surfaces.

Last Opinion

Both Loctite 246 and 243 are reliable thread locker adhesives that can provide a strong seal for your threaded fasteners.

A good-general purpose thread locker that can handle moderate shock and temperature variations is Loctite 243. Loctite 246 may be a better choice if you need a thread locker that can handle heavy-duty applications, high temperatures, or corrosive environments.

Here, I tried to make a comparison between Loctite 246 Vs. 243, to help you understand their differences. Hopefully, now you have a good overview of them.