You can use threadlockers to safely secure your bolts, nuts, and other threaded fasteners from loosening due to shock and vibration.

Loctite manufactures various threadlockers in multiple segments that can suit your purpose well. Loctite offers threadlockers for different sizes of fasteners in multiple strengths and viscosities.

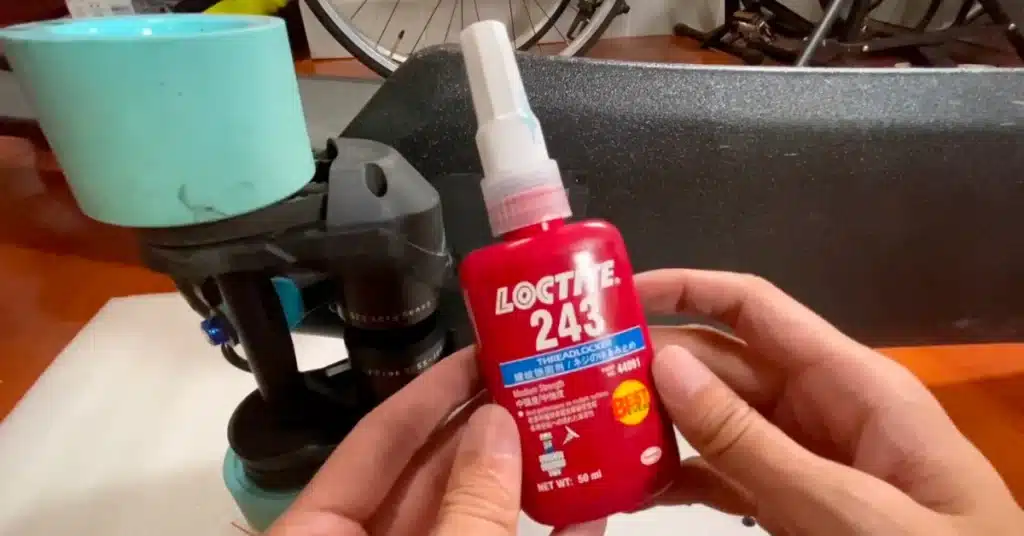

Loctite 242 and Loctite 243 are both medium-strength threadlockers from Loctite with some standard features and differences.

Furthermore, both come in Blue, so in the battle between Loctite 242 vs. 243, which one should you side with and why?

I’ll review the features and specifications of Loctite 242 and 243 and how they differ. So, keep reading if you want to decide which one to pick.

Read More: Loctite 242 vs. 262

Loctite 242 vs. 243

Overview of Loctite 242

Loctite offers four colors of threadlockers, indicating their strength and intended purposes. Loctite 242 is a blue-colored threadlocker manufactured by Loctite-Henkel, meaning it has medium strength.

Loctite 242 is based on dimethacrylate-ester and has a medium viscosity of 800 to 1600 cP. The 242 cures anaerobically when confined in the vacuum between confined metal spaces.

Loctite 242 works well with all metals and passive substrates like – brass, steel, or stainless steel.

After application, Loctite 242 takes around 24 hours for a complete cure, with the curing speed depending on the substrates used, bondline gap, and temperature.

You can use 7471, 7649, 7088, or 7091 activators to speed up the curing process. Loctite 242 is tolerant to contamination from anti-corrosion fluids and various industrial oils.

The 242 has a swift fixture time of only 5 minutes for steel, with a slightly longer fixture time for brass and stainless steel of 15 and 20 minutes, respectively.

You can use Loctite 242 for various components around your house or office, like – pumps, gearboxes, motors, transmission systems, suspension, and more.

Loctite 242 is suitable to use with components with temperatures reaching up to 149°C or below-freezing temperatures up to -54°C. You can use Loctite 242 for bolts, nuts, or threaded fasteners up to M20 in size.

You can buy Loctite 242 from a tube weighing .5 ml to a bottle weighing 1 liter.

Overview of Loctite 243

The 243 is a blue-colored, medium-strength threadlocker manufactured by Loctite-Henkel. Loctite 243 cures when confined between close-fitting metal spaces and is based on dimethacrylate-ester.

You can use Loctite 243 to safely secure bolts, nuts, or threaded fasteners in place in components with a risk of exposure to constant shock or vibration. Loctite 243 works well with all metals and standard substrates.

Loctite 243 has a medium viscosity of 2150 cP and is thixotropic. Loctite 243 is versatile and works well with all metals and on steel, plated surfaces, aluminum, and more.

You can use the 243 for various equipment and components around your house, office, or industry, like – light machinery, grills, motors, and more.

Furthermore, you can also use it for pumps and various automotive parts like – transmission or suspension systems, oil pans, and more.

Read More: Loctite 242 vs. 271

Loctite 243 protects against contamination from various oils, lubricants, and fluids like – cutting oils, lubricators, anti-corrosion fluids, and other contaminants.

Furthermore, Loctite 243 can be used for components with temperatures rising to 180°C or in freezing conditions with temperatures down to -55°C.

If you plan to disassemble your components later, use standard hand tools like – a wrench. However, if you have trouble disassembling your components you can use solvents and apply localized heat.

Differences Between Loctite 242 And 243

Let’s take a look at how Loctite 242 and Loctite 243 differ.

Glue Strength and Ideal Uses

Loctite 242 and Loctite 243 are blue-colored threadlockers from Loctite-Henkel, indicating they have medium strength.

Furthermore, they are both dimethacrylate-ester-based adhesives and cures anaerobically, so they have some similar features.

You can use Loctite 242 or 243 for various equipment around your house, office, or industrial equipment like motors, power equipment, and mowers.

Since both products offer enhanced protection against shock or vibration and are tolerant to various oils and contaminants, you can use them for automotive purposes like for your transmission, valve covers, and alternators.

Loctite 243 is newer than Loctite 242 and has more oil tolerance.

Viscosity

Loctite 242 and 243 both have medium viscosity and are thixotropic.

The 242 has a viscosity of 800 to 1600 cP.

On the other hand, the 243 has a higher viscosity of 2150 cP. Since Loctite 243 is thicker in composition compared to the 242, it’s more suitable for you if you’re working with rough edges or significant gaps.

Suitable Thread Size

Loctite 242 is suitable to use for nuts, bolts, and threaded fasteners up to M20 in size.

On the other hand, Loctite 243 is suitable for nuts, bolts, and threaded fasteners up to M18 in size.

ServiceTemperature

Loctite 242 has a service temperature rating of -54°C to 149°C.

On the other hand, the 243 has a service temperature rating of -55°C to 180°C.

Fixture and Cure Time

Based on the materials and substrates you use, Loctite 242 has a fixture time ranging from 5 to 20 minutes.

On the other hand, Loctite 243 has a fixture time of 10 minutes.

After you apply, Loctite 242 and 243 have a similar cure time of around 24 hours. The cure time depends on temperature, bondline gap, and substrates used. You can speed up the curing process using activators.

Removal

Since Loctite 242 and 243 are both medium-strength, blue-colored threadlockers from Loctite, they can be removed if you plan to disassemble your components.

You can use standard hand tools like a wrench to remove parts you used either threadlockers on.

However, if you have trouble disassembling your components, use a methylene chloride solution or localized heat.

Read More: Loctite 248 vs. 242

What is equivalent to Loctite 242?

Loctite 242 is a medium-strength, blue threadlocker commonly used to prevent loosening of metal fasteners due to vibration. It can be removed with hand tools for easy disassembly if needed.

Several other brands offer similar products, but the name may vary. Some equivalents include:

1. Permatex Medium Strength Threadlocker Blue (part number 24200)

2. 3M Scotch-Weld Threadlocker TL42

3. Vibra-Tite VC-3 Threadmate

4. Hernon ReAct 784

5. J-B Weld 271 Threadlocker

Remember, while these are equivalents, they might not perform exactly the same way as Loctite 242. Always read the product details to ensure the threadlocker meets your specific needs.

Is Loctite 243 removable?

Yes, Loctite 243 is a removable, medium-strength threadlocker. It’s an updated version of Loctite 242, with added capabilities to work better on passive metals and withstand more chemical resistance from motor oils.

Like Loctite 242, it can be removed using hand tools, making it a good choice for fasteners that might need to be serviced.

Can I use Loctite 242 instead of 243?

Yes, you can generally use Loctite 242 instead of Loctite 243, as both are medium-strength, removable threadlockers. They are designed to prevent loosening from vibration on metal threaded fasteners and can be removed with hand tools.

However, Loctite 243 is an upgraded version of 242 that offers better performance on passive metals (like stainless steel and plated surfaces), more oil tolerance, and higher temperature resistance.

So, Loctite 243 might be the better choice if your application involves such conditions.

Always read the product specifications and use instructions to confirm your application’s suitability.

Last Opinion

Loctite 242 and 243 are excellent threadlockers for safely securing threaded fasteners in various components around your house, office, and industry.

Furthermore, they have various similar features and are both medium-strength threadlockers. So, which one should you side with in the battle between Loctite 242 vs. 243?

Loctite 243 is newer compared to Loctite 242 and has some better features, and is more oil resistant.

However, Loctite 242 can work with threaded fasteners up to M20 in size. So, it depends on you and your specific purpose to pick between Loctite 242 or Loctite 243.

Very well written article. I walked away learning exactly what I needed know and didn’t leave with any outstanding questions or obscurity. Thank you!

Thank you, Fonkin.