In any construction project, whether it’s building a house, repairing some structural damage or simply making repairs to your own home, you’ll come across one or more of these 15 types of adhesives used in construction.

Whether you’re doing the actual construction yourself or hiring someone else, you’ll want to know what type of adhesive you need, as some are better suited to specific projects than others.

This guide will help you understand how each type of adhesive works and which ones should be used under which circumstances so that your project goes smoothly and on time.

What is Construction Adhesive?

Regarding construction adhesive, there are two main types: water-based and solvent-based.

Water-based adhesives are composed of adhesive, water, and small amounts of other ingredients. Solvent-based adhesives typically contain solvents along with adhesive and stabilizers.

The primary purpose of construction adhesive is to bond surfaces together so that they become inseparable under normal conditions; however, once cured, some will form a cohesive material all by themselves.

One last thing you should know about construction adhesives is that despite their different compositions and methods for curing, both have an unlimited shelf life when stored at room temperature.

Read More: Types of Adhesives Used in Packaging

Types of Adhesives Used in Construction

The main types of adhesives used in construction: Water-Based Cement, Epoxy Cement Polyurethane, Glue Hot Melt Adhesive, Spray Foam Insulation, Silicone Sealant, Wood Glue, Casein/Protein-Based Glues, Acrylic Adhesive, Anaerobic Adhesive, Pressure Sensitive Adhesive, UV Curing Adhesive, Solvent-Based Adhesive, Reactive Adhesive, Plastisol Adhesive.

1) Water-Based Cement

Water-based cement is an adhesive that has several different names, including modified epoxy and polyurethane. In most cases, they are used to bond metal to wood.

Water-based cement usually comes pre-mixed with a catalyst but can also be mixed on-site. It is applied with a caulking gun and dries within minutes.

Once dry, water-based cement is practically waterproof and unaffected by water exposure or fluctuations in humidity levels.

There are many good reasons why water-based cement adhesive are popular among carpenters:

- They dry quickly.

- They have excellent adhesion properties.

- They last for years.

- They don’t require priming or sealing when applied to specific substrates such as hardwood.

2) Epoxy Cement

Epoxy cement is a type of adhesive used to stick metal to metal. It is often used as a sealant or coating and can come in clear or pigmented varieties. Construction adhesive and epoxy has some differences.

Epoxy cement is known for its adhesion, strength, and durability, making it great for applications like boat building or repairing car bodies. If you want an adhesive perfect for bonding metals to metals, epoxy cement is your best bet!

3) Polyurethane Glue

Polyurethane glues were developed as alternatives to epoxy adhesives. Epoxies are composed of two components, a resin and a hardener, which must be combined at a specific ratio and temperature before application.

If stored incorrectly or applied too thickly, epoxy glues can leave unsightly yellow stains on drywall and wood. Polyurethanes are made from a single component: polyurethane resin.

Because they’re typically easier to apply than epoxies and have less odor, polyurethane glues are gaining popularity among contractors in various trades and industries who require strong adhesion between parts while maintaining water resistance.

Read More: Subfloor Adhesive vs. Construction Adhesive

4) Hot Melt Adhesive

Hot melt adhesives are rubber glues. These adhesives are most commonly used for bonding non-porous surfaces together, such as a hot glue gun or instant glue sticks.

The second you want to take an item apart, hot melt adhesive can make your life miserable. That’s because you’ll have to wait for it to cool down before picking it up with your fingers or a pair of pliers.

If you need an instant bond that will hold things tightly until you’re ready to come back and deal with them later, these may be perfect for you. They tend to cost less than other types of adhesives and can handle high temperatures well when necessary.

Read More: Best Construction Adhesive For Concrete

5) Spray Foam Insulation

Spray foam insulation is a popular choice for professional builders and DIY homeowners looking to make their homes more energy-efficient.

While it can be expensive, it also offers several benefits that will quickly offset that initial cost—and here’s why.

There are two basic types of spray foam: Open-cell and closed-cell. Open-cell spray foam has tiny holes that allow air to move freely through it, making it more breathable than closed-cell spray foam, making you feel warmer during cold weather and preventing heat from escaping.

Regardless of which type you choose, both create an excellent barrier between your home and the outside temperature.

6) Silicone Sealant

Silicone sealants fill gaps in windows and doors, so they don’t allow air, moisture or pests to enter. The material helps prevent energy loss and protects building materials from the weather.

Silicone sealant can be used in construction jobs such as repairing a roof, mending a concrete foundation or shoring up a wall with rotten wood. It is commonly sold in tube or cartridge form for caulking guns, though it can also be found in squeeze bottles for use by hand.

Since silicone sealant cures at room temperature and permanently bonds with building materials, you have time to apply several coats until you achieve a level of coverage you are happy with. Silicone sealant comes in the clear but can also be purchased tinted for aesthetic purposes if desired.

Read More: How To Use Construction Adhesive Without Gun?

7) Wood Glue

Wood glue is most commonly used for woodworking, though it can also bind other materials. It’s a sticky liquid that forms a tough bond once it dries.

The bond is usually stronger than what you’ll get with nails or screws but not as strong as other types of adhesives such as epoxy resin. There are some difference between construction adhesive and wood glue.

Wood glue comes in two varieties: yellow carpenter’s glue and white or yellow PVA (polyvinyl acetate) glue. Though they are interchangeable, yellow carpenter’s glue tends to be stronger and gives off a stronger odor while drying. Wood glue is typically applied using either a trowel or paintbrush.

8) Casein/Protein-Based Glues

Casein-based glues are made from milk proteins. Casein/protein-based glues are used in various applications and settings, including construction.

These adhesives offer strong bonding capabilities that can hold heavy objects together well in wet and humid environments, which is ideal for use in construction sites that often see rain or other types of weather.

Casein-based glues are also resistant to moisture and chemicals, making them a great choice when you need your object to hold together underwater or even in extreme weather conditions.

There are quite a few different kinds of casein/protein-based glues on the market today; each has its chemical composition and characteristics, so it’s important to learn about all your options before deciding on one.

9) Acrylic Adhesive

Acrylic adhesives are formulated to become more resilient and durable as temperatures rise. Because they’re designed to adhere well in high-temperature situations, acrylic adhesives are used in several construction applications. For example, they’re often found in car body panels.

Acrylic adhesives also have excellent resistance to ozone degradation, so you can be confident that these adhesives will remain bonded as you drive through warm sunny days and cold, humid nights.

There is some debate about whether or not using an acrylic adhesive will make your parts more brittle – but most professionals agree that acrylic adhesives offer strength and durability in all conditions.

10) Anaerobic Adhesive

When there’s not enough oxygen in space for the adhesive to cure, it’s known as anaerobic. Anaerobic adhesives are used for those working in enclosed environments like underwater or underground construction.

Plastic bonding agents like epoxies and polyurethanes hold up well in anaerobic conditions; their reactions happen without oxygen.

The agent is activated by heat, pressure, or chemical catalysts instead. An advantage of these adhesives is that they can be easily removed at a later date without leaving behind residues on surfaces or causing damage to the materials they were attached to.

However, some situations do require builders to use other options.

11) Pressure Sensitive Adhesive

Pressure-sensitive adhesives are considered one of many tack (short for tackiness) adhesives that dry with an adhesive bond. They can be used in various applications and materials, as they’re particularly efficient in low-stress environments (think: labels, booklets, mailings).

Pressure-sensitive adhesives are also used to affix price tags to merchandise in retail stores. If you’re looking to play it safe—or want it done right—you’ll want to choose a pressure-sensitive adhesive for your construction project.

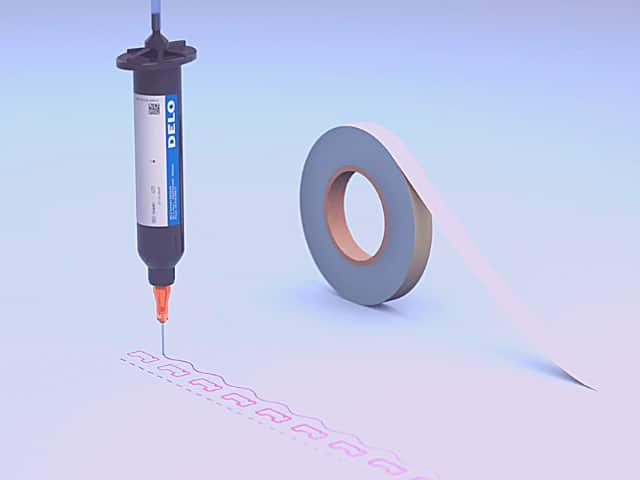

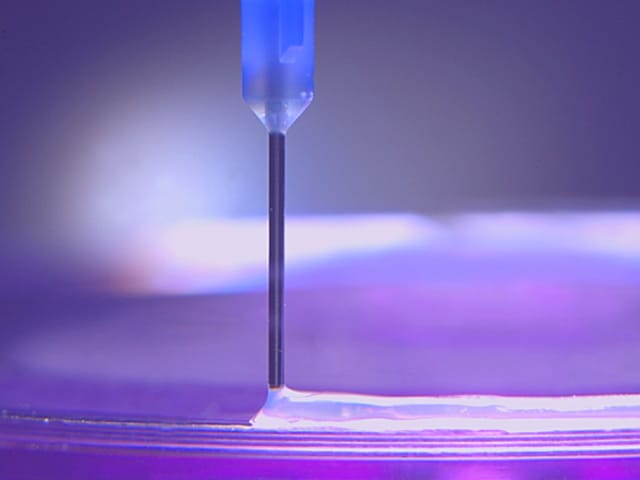

12) UV Curing Adhesive

UV Curing Adhesive is a water-based adhesive that bonds to various surfaces. It is used in construction primarily for its ability to cure with UV light but also because it has a minimal environmental impact.

UV Adhesive can be used for special effects in construction as well. When properly applied, UV Adhesive helps create waterproof and seamless coatings without breaking down or cracking over time.

13) Solvent-Based Adhesive

Solvent-based adhesives are commonly used in construction to bond metal, plastic, and rubber. They’re also used in less-visible applications like car assembly. The adhesive is typically sprayed or brushed onto surfaces and left to dry before being assembled.

The glue’s chemical composition dissolves as it dries, leaving a strong bond between surfaces. Solvent-based adhesives can be fast-drying or self-curing depending on their application; for example, fast drying solvent adhesive can be used in situations that require fast assembly.

14) Reactive Adhesive

Reactive adhesives cure through a chemical reaction between two separate components mixed right before application. It is most commonly used in construction.

This type of adhesive is great for bonding various surfaces such as metals, ceramics, concrete and more.

Reactive adhesives can be found at almost any hardware store and are inexpensive compared to other types. These adhesives are commonly used with fasteners like screws or nails; they make it easy to secure an object into place without much hassle.

These adhesives have water resistance properties and can handle pressure during construction projects well.

However, reactive adhesives must be fully cured before they’re exposed to water or moisture because otherwise, they could break down and become useless.

15) Plastisol Adhesive

Plasticiser is an adhesive that holds synthetic fibers such as glass, nylon and polyester together with a fabric backing. Plastisol is especially useful for making stiff felt used in construction.

Typical uses for plastisol include headliners in cars and truck interiors, underlayment for artificial turf and carpeting, motorcycle leathers and vehicle seat backs. Plastisol is also used in construction applications, including concrete reinforcement mesh, window blinds, shutters and window awnings.

Unlike most adhesives used in construction that harden when heated or cured (such as urethane glue), plastisol softens to create its bond through a chemical reaction called esterification.

Last Opinion

It is necessary to understand that each type has its purpose and function. You need to pick what is right for your project. If you are building something, you have to consider many things like durability, flexibility, sturdiness and several other elements.

With all these factors considered, I would opt for an adhesive that gives me all the perks mentioned above, such as hot melt adhesives. These adhesives ensure that my structure does not fall apart or wobble no matter how hard it gets used. So if you are looking for sturdy and flexible adhesives, consider getting hot melt ones.