Loctite 510 and Loctite 515 have similar names and numbers, and they also work for a similar purpose.

And because of all these similarities, more often than not, you might get confused about which one to buy for your project and what to leave behind.

To remove all your confusion and also to help you make a wise buying decision, here, I have compared Loctite 510 vs. 515 in great detail.

Just go through the comparison below for further understanding.

Read More: Loctite 510 vs. 518

Loctite 510 vs. 515

What is Loctite 510?

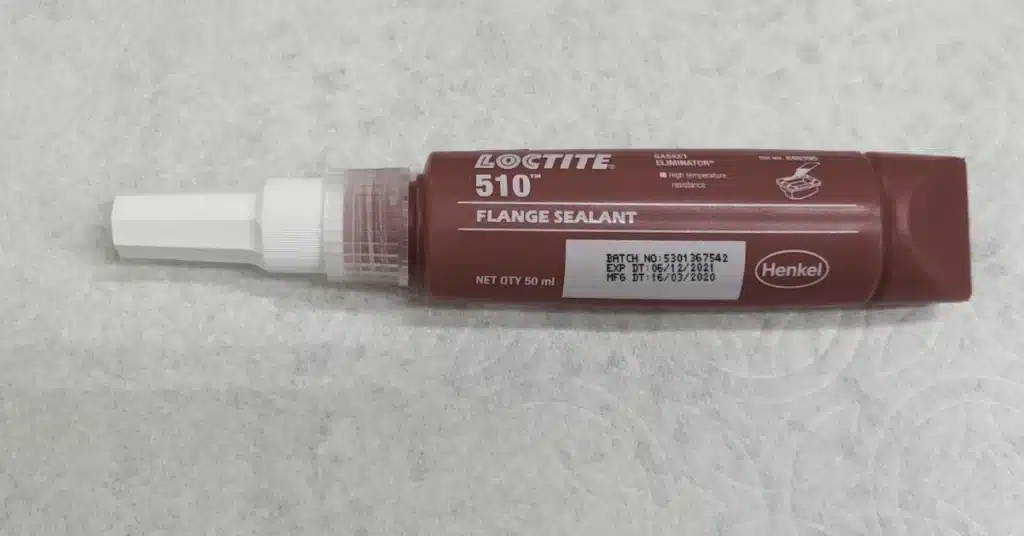

Loctite 510 is an anaerobic sealant, specifically a gasket eliminator flange sealant. It’s part of the Loctite brand of adhesives and sealants, known for their quality and effectiveness in various industrial and mechanical applications.

This product is designed to provide high-temperature-resistant sealing and bonding. It is typically used for sealing rigid flange faces, such as transmissions and engine casings.

It helps create a seal that can withstand high temperatures, preventing leakage of fluids like oil or coolant.

Loctite 510 cures when confined without air between close-fitting metal surfaces. This characteristic makes it ideal for sealing metal flanges that are not frequently disassembled.

The cured sealant is also resistant to a range of chemicals and solvents, making it versatile for use in harsh environments.

Its popularity in industries is due to its reliability and effectiveness in providing long-lasting, leak-proof seals under various conditions, including high temperatures and exposure to different chemicals.

What is Loctite 515?

Loctite 515 is an anaerobic adhesive specifically designed as a gasket maker or flange sealant. It is part of the Loctite brand, which is widely recognized for producing high-quality adhesives and sealants for industrial and mechanical applications.

Loctite 515 is formulated to cure when confined in the absence of air between close-fitting metal surfaces. It’s used for sealing rigid flange faces, particularly where there might be gaps or imperfections on the surface.

This makes it suitable for applications like gearbox casings, engine blocks, and similar assemblies requiring a robust, flexible seal.

This product is known for its excellent oil resistance and its ability to seal close-fitting joints between rigid metal faces and flanges.

It provides a flexible yet strong and durable seal that helps prevent leakage of fluids and gases. It’s particularly effective in environments where there might be slight flexing or movement, as it can adapt without losing its sealing properties.

Loctite 515 is a versatile sealant that is easy to apply and cures rapidly at room temperature. It’s widely used in various industries due to its effectiveness in creating leak-proof seals, even under challenging conditions.

Read More: Loctite 515 vs. Loctite 518

Quick Comparison

Even though both the Loctite 510 and Loctite 515 are gasket sealants and from the same brand, there are more than a few differences between them.

But before jumping into the detailed explanation and discussion, have a quick look at the table below for a summary of the differences.

| Properties | Loctite 510 | Loctite 515 |

| Viscosity | 40,000 | 3,75,000 |

| Tensile Strength | 1,085 psi | 2,030 psi |

| Temperature Resistance | 400°F | 300° F |

| Color | Pink | Purple |

| Curing Time | 24 hours | 12 hours |

| Price | A bit high price | Moderate |

What Are The Differences Between Loctite 510 and 515?

Now that you have an idea about the differences, it’s time to discuss how Loctite 510 and Loctite 515 differ in great detail.

Keep on reading below to find out more.

#1 Tensile Strength

The performance of an adhesive or gasket sealant greatly depends on the tensile strength of the formula. And when it comes to strength, there is a notable difference between the Loctite 510 an Loctite 515.

For starters, Loctite 510 is a medium-strength gasket sealant that offers a tensile strength of 1,085 psi to create a strong and durable bond.

However, when it comes to the Loctite 515, the story is a bit different. As this sealant offers a tensile strength of 2,030 psi, it creates a super strong and more robust bonding for a durable adhesion.

#2 Temperature Resistance

How much heat or temperature a sealant can resist says a lot about its adhesion and durability.

Even though Loctite 510 is a low-viscosity sealant with moderate strength, it can withstand up to 400°F of heat before melting.

Because of such a high-temperature-resistant feature, this adhesive is more durable than many of its close competitors.

On the contrary, Loctite 515 can resist 300° F of heat and doesn’t stay in place as long as its competitor.

Because of this, Loctite 515 isn’t as durable as 510 sealant.

#3 Curing Time

Because both the Loctite 510 and Loctite 515 have different viscosity and consistency, their cure time is also different.

For instance, as Loctite 510 is a low-viscosity gasket sealant, it takes about 24 hours to dry and cure properly.

On the other hand, the cure time of Loctite 515 is much less. Because it is a medium-viscosity adhesive, it requires around 12 hours to cure. You can start working with the bonded surface quicker than anticipated.

Last Opinion

After comparing Loctite 510 vs. 515 in great detail and with utmost attention, I am determined that I will buy the Loctite 515 over Loctite 510 on any given that.

That is because Loctite 515 is a high-strength, high-viscosity sealant that can create a strong bond between surfaces. It also cures quickly for the user’s convenience.

Moreover, even though this adhesive comes with all amazing features, it is moderately priced so that anyone and everyone can buy it/