Loctite is a well-known brand in the world of adhesives and is used by professionals and non-professionals.

Loctite makes various adhesives in multiple segments, and you will always find alternatives when getting a Loctite adhesive.

Loctite makes multiple types of glues like – threadlockers, sealants, instant adhesives, retainers, and more.

Loctite 609 and 638 are retainers manufactured by Loctite-Henkel and have similarities and dissimilarities.

So, in the battle between Loctite 609 vs. 680, which one should you side with and why? I’ll review Loctite 609 and 680 features and differences in this article.

Read More: Loctite Blue vs. Red

Read More: Different Types of Loctite

Loctite 609 vs. 680

Loctite 609 Overview

Loctite 609 is a green-coloured retaining compound manufactured by Loctite-Henkel. The 638 is a high-strength adhesive and uses acrylic technology to cure.

Loctite 609 is positive and fluoresces under UV light, so you can use UV lights to monitor your components once you use the 609. You can use the 609 to bond between cylindrical fitting parts.

Loctite 609 cures anaerobically and forms a robust bond when completely cured, which takes around 24 hours after application. The 609 cures when confined in a vacuum between close-fitting metal parts.

Furthermore, the 609 is a high-strength retaining compound, and you can use it for components with a risk of shock or excess vibration exposure. When Loctite 609 is wholly cured, it has enhanced protection against the loosening of your parts or leakage due to exposure to excessive shock or vibration.

Loctite 609 is a low-viscosity, high-strength adhesive, so you can use the 609 if you’re looking for a high-strength adhesive with less risk of the uncured adhesive running over the surface.

Loctite 609 works on active metals and common passive substrates like stainless steel. Loctite 609 can take up to 24 hours for a complete cure, and the cure time depends on the materials you use, the temperature and the bondline gap. You can speed up the curing process with activators like SF 7471 or SF 7649.

Read More: Loctite 620 Vs. 680

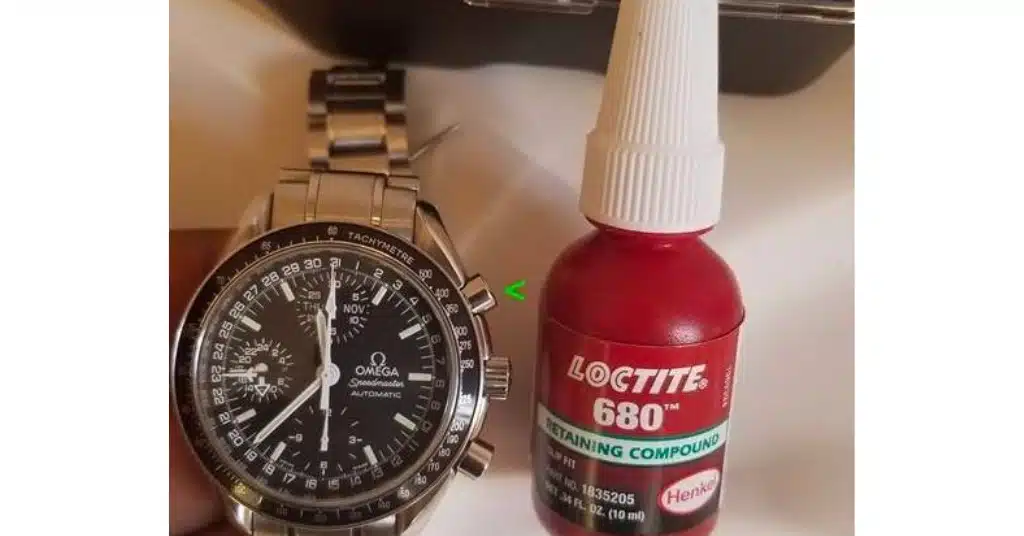

Loctite 680 Overview

Loctite 680 is a green-coloured retaining compound manufactured by Loctite-Henkel, and you can use it for close-fitting cylindrical parts.

Loctite 680 works with active metals and passive substrates like – stainless steel or plated surfaces. Furthermore, Loctite 680 is a high-strength retaining compound made by Loctite-Henkel and has a robust performance when completely cured.

After a complete cure, Loctite 680 prevents your components from loosening due to shock or vibration. Additionally, Loctite 680 also has enhanced protection against leakage due to shock or vibration. Loctite 680 fluoresces under UV light, and you can monitor your components under UV light after you apply the 680.

Loctite 680 has high-temperature tolerance, and you can use it for components that have a risk of the temperature getting high or fluctuating. Loctite 680 has ANSI/NSF 61 certification, which means you can use the 680 for indoor or outdoor water systems as long as the temperature doesn’t exceed 82 °C.

Furthermore, Loctite 680 is also tolerant to minor contamination on the surface level from common industrial oils like – cutting, lubrication, anti-corrosion and protection fluids.

Read More: Loctite 603 vs. 609

Differences Between Loctite 609 vs. 680

Now let’s examine how Loctite 609 and 680 differ.

Ideal Applications

Loctite 609 is a high-strength retaining compound manufactured by Loctite-Henkel, and you can use it to lock bushings and sleeves in housings or shafts and augment press fits. You can use it for other retaining purposes indoors and outdoors.

On the other hand, Loctite 680 is a high-strength retaining compound you can use for loose-fitting parts, slip-fitted parts and other retaining purposes. Loctite 680 has ANSI/NSF 61 certification for high-temperature usage, and you can use it for water systems that do not exceed 82 °C.

Viscosity

Loctite 609 and 680 are both low-viscosity adhesives from Loctite-Henkel.

Loctite 609 has a viscosity of 120.0 mPa·s (cP).

On the other hand, the 680 has a higher viscosity rating of 750.0 – 1750.0 mPa·s (cP).

Fixture and Cure Time

Loctite 609 and 680 take around 24 hours for a complete cure, depending on the materials used, bondline gap and temperature. You can speed up the curing process using an activator.

Loctite 609 has a fixture time of 4 minutes.

On the other hand, the 680 has a slightly longer fixture time of 10 minutes.

Read More: Loctite 565 vs. 567

Last Opinion

Loctite 609 and 680 are similar in multiple ways and only have minor differences, so which one should you side with in the battle of Loctite 609 vs. 680?

You can go for the 609 if you need a lower-viscosity retaining adhesive and plan to use it for the purposes listed in the ideal application’s sections.

Loctite 680 would be your perfect pick if you can work with a slightly higher viscosity adhesive.